Global Digital Twin Market to Reach USD 195 Billion by 2030

According to the latest market research study published by P&S Intelligence, the digital twin market is set to grow at a compound annual growth rate (CAGR) of 49.9%, reaching a staggering USD 195,347.6 million by 2030. This growth is primarily driven by the increasing adoption of IoT, AI, 5G, Industry 4.0, and machine learning (ML) technologies. Additionally, the rising focus of the manufacturing sector on digital twins to lower costs and enhance supply chain operations, the growing demand in healthcare, and the preference for cloud-based solutions further fuel market expansion.

Small and medium enterprises (SMEs) have significantly contributed to the digital twin market and are expected to grow at a CAGR of 52.2% in the coming years. This is attributed to their swift digital transformation and the rising need for virtual modeling solutions. These technologies enable SMEs to design better products, predict issues early, and schedule maintenance efficiently, reducing downtime and improving product performance. SMEs are increasingly adopting digital twin solutions to enhance product quality, improve operational efficiency, and maintain competitiveness in the market.

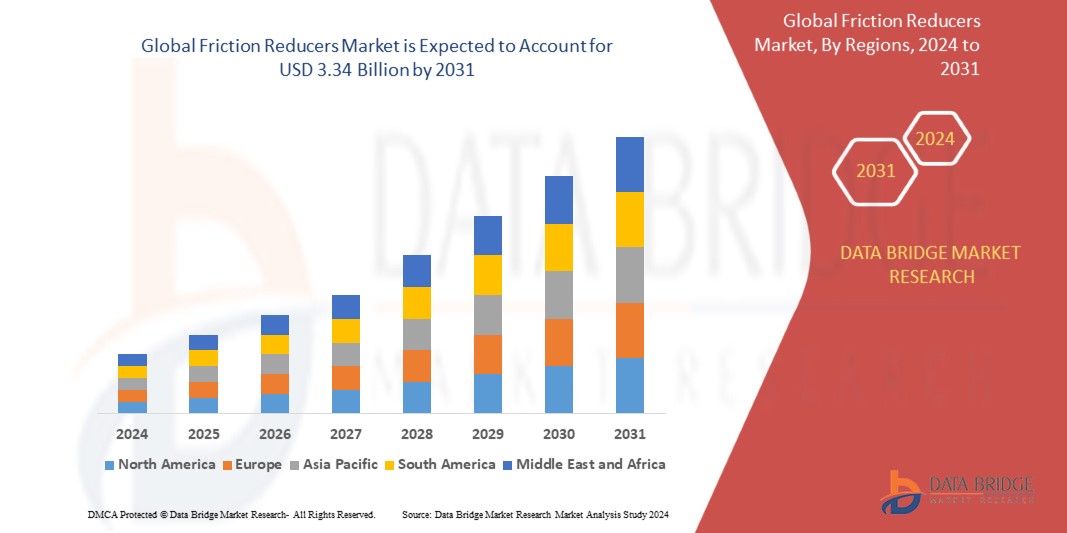

North America has been leading the digital twin market, holding a 36% share in the past. This dominance is linked to the region's early adoption of advanced technologies, such as AI, IoT, and ML, coupled with a strong IT infrastructure and a focus on Industry 4.0 standards, especially in the manufacturing and automotive sectors. According to GSMA Intelligence, IoT revenue in North America is projected to reach USD 337 billion by 2025, nearly three times the 2018 figure.

Make inquiry before purchase of this report: https://www.psmarketresearch.com/send-enquiry?enquiry-url=digital-twin-market

The product segment accounted for the largest revenue share and is expected to maintain this position in the coming years. Digital twin technologies allow businesses to collect detailed data on product performance, reducing mean time between failures (MTBF) and mean time to repair (MTTR). This improves system efficiency, reduces costs, and enhances productivity. In the aerospace industry, significant investments in part design and development have led to the use of digital twins for creating innovative designs while minimizing costs. Aerospace companies utilize these solutions for designing critical components like avionics, thermal protection systems, and airframes.

Moreover, the healthcare industry's growing demand for digital twin solutions has significantly contributed to the market's expansion.